To assist UWRT in completing the Ocean Cleanup task, the Team is introducing our newest robot the S.S. Flip Barker (SSFB). This AUV is designed to be both capable of traveling the open water and land operation. To enable both land and water operation, the SSFB is equipped with a 0.8 horsepower drivetrain equipped with two electric motor protected by UWRT’s custom shaft seals. Utilizing this drivetrain, the SSFB will land on the ocean cleanup task and collect trash via its claw.

To facilitate open water operation, the SSFB is equipped with two thrusters and a ballasting system. The ballasting system allows the AUV to change its net buoyancy by filling its tanks with stored air or flooding them with water. In the water, the SSFB will communicate with Talos via UWRT’s Inter Vehicle Communication (IVC) system. As a parting piece, the SSFB features a Noodle Winch system to allow the AUV to surface without leaving the surface of the Ocean Cleanup task.

At a glance:

- Custom IVC solution with an In-House Built Transducer

- Active Ballasting System with Pressure Monitoring

- 0.8 Horsepower Drivetrain with Sealed Brushed Motors

- 2 BTD150 Brushed Thrusters

- Electromagnet Towing Hookup, Rack, and Pinion Claw

- Jetson Orin Nano as Primary Vehicle Computer

- VectorNav VN 100-T IMU

- Stereolabs ZED X Mini + YOLOv11 for Computer Vision

- 3X Blue Robotics Bar 02 Pressure Sensor for Depth Measurment and Buoyancy System Monitoring

- Using UWRT’s Riptide Software Codebase

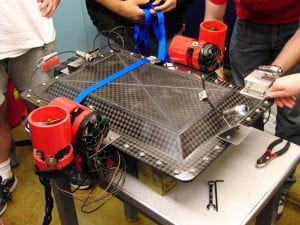

Talos is our main robot. Design started early August 2022 in Maryland, where we had just finished competition at RoboSub 2022! The design goals for Talos were pulled from Tempest’s shortcomings. This included plans to strengthen the chassis, design a next gen electronics system: Mark II, and create hassle-free smart battery housings. Further improvements have been made through the 2023-2024 and continuing into the 2024-2025 academic years to increase Talos’s reliability. Specifically, new 3-D printed internal Guide Rails, updated Actuators and Torpedoes, and the installation of a custom, student-built Transducer.

At a glance:

- 8 thrusters providing 6 degrees of freedom

- Two central housings containing vehicle electronics

- Rigid chassis built from 6061 Aluminum

- VectorNav VN-100 IMU, Nortek DVL 1000-300m, Fizoptika Fiber Optic Gyro, and Blue Robotics Bar02 Depth sensor

- StereoLabs Zed X Stereo Camera (forward facing) and Zed X Mini Stereo Camera (downwards facing) for computer image detection using YOLOv11 Segmentation

- Nvidia Jetson Orin as the primary vehicle computer

- Custom designed vehicle electronics

- Hot-Swappable Batteries

- Custom Sliding Mode and PID hybrid controller

- Competed in RoboSubs 2023 & 2024

- 100s of hours of swimming

We would like to happily announce that our vehicle, Talos, has successfully completed RoboSub prequalification!

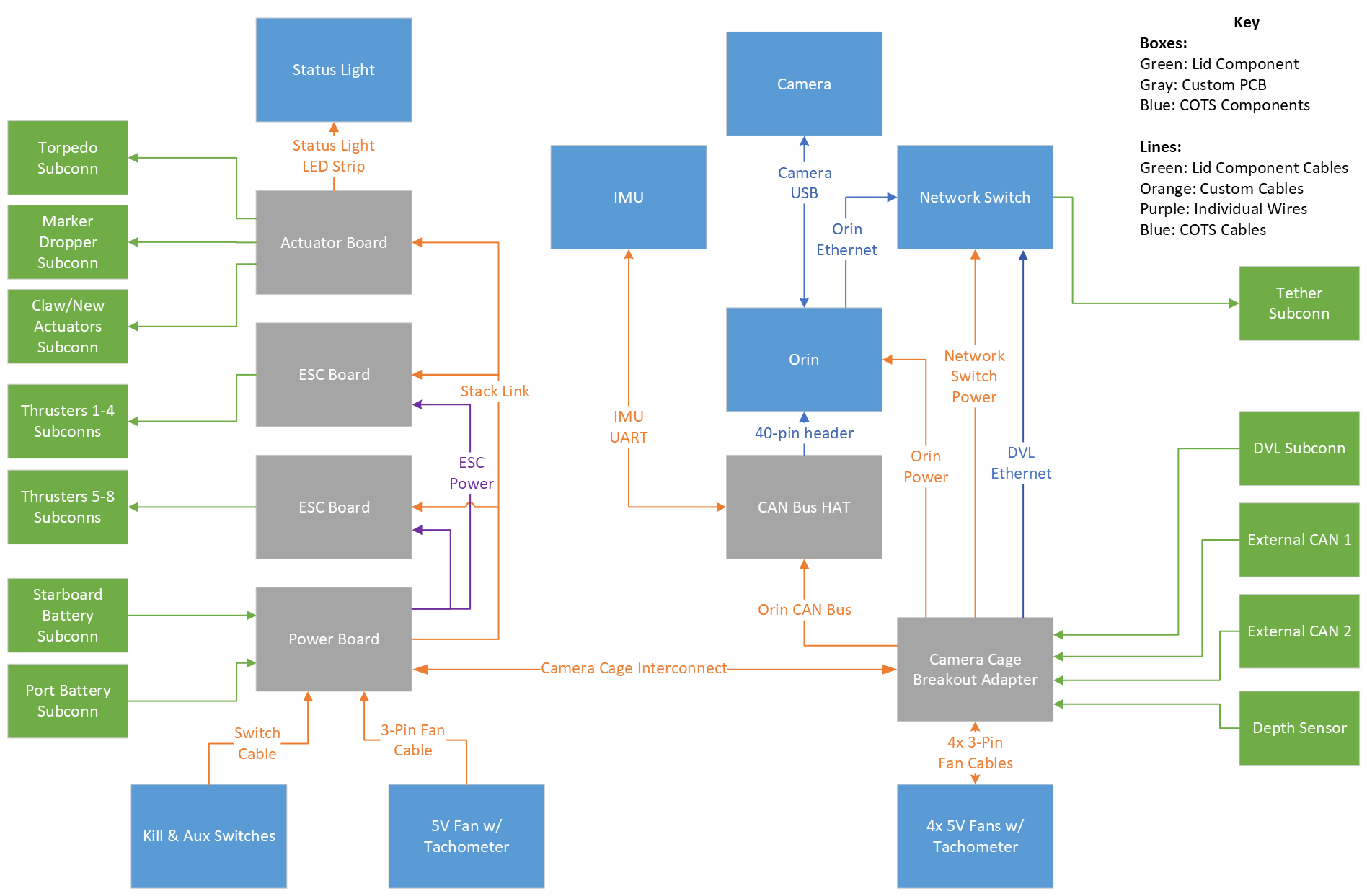

The Mark 2 electronics is the next generation electronics running Talos. These electronics were primarily developed throughout the 2022-23 academic year, taking lessons learned from Tempest’s Mark 1 electronic system to make a more reliable and polished electronics system. The electronics system underwent the following changes:

- Distributed architecture with each circuit board containing an independent microcontroller communicating over CAN Bus

- Switched the physical layout of the electronics to increase circuit board density

- Increased telemetry available from the electronics system to allow for complete system diagnostics over the network

Read more about the team’s electrical systems on the Navionics Team Page

Diagram of Mark 2 Architecture:

Talos has undergone many improvements to the mechanical systems throughout the vehicle’s redesign. Some of these include:

- Pocketed lids to reduce weight, overall 2.7 kg lighter than Tempest

- Improved thruster cable management to reduce drag

- Electronics cages mounted on rails, enabling consistent IMU placement and easy modifications

- Higher rigidity with new structure verified by FEA

- Thruster guards to protect against impacts with walls

- Modular task mechanism mounting

- New task mechanisms, with torpedoes and markers being integrated together

- Smart battery housings

- Adjustable center of mass position by indexing battery rails

- Reduced width, allowing it to fit through a door

- Ergonomic handles for easier transportation

- Anodized for added protection

Read more about these improvements on the Mechanical Team Page

Talos uses the same Riptide Software stack of all of our previous AUVs. This year a focus was placed on improving the testability of our software systems, with several new systems created for this purpose:

- New editor developed for robot task code to reduce common errors faced during development

- Automated tests written for robot task code to minimize crashes during competition runs

- Improved visualization tools to view and operate the vehicle during pool tests

- Tools to allow vehicle operation without needing command line interface

Read more about the team’s software systems on the Software Team Page

Previous AUVs

Tempest - Competed in Robosub 2022

As the predecessor to Talos, Tempest’s development began in January 2020 and was initially supposed to compete in RoboSub 2021. Unfortunately, due to roadblocks put in place by the COVID-19 pandemic, production was delayed leaving Tempest’s first and only competition in 2022 at RoboSub.

As the predecessor to Talos, Tempest’s development began in January 2020 and was initially supposed to compete in RoboSub 2021. Unfortunately, due to roadblocks put in place by the COVID-19 pandemic, production was delayed leaving Tempest’s first and only competition in 2022 at RoboSub.

Puddles - Competed in RoboSub 2019 & 2020

Puddles was developed over the course of 2018-2019 and 2019-2020 school years. Competing in RoboSub 2019 the AUV placed 11th out of 55 teams and once again in 2020 placing 10th out of 33 teams. With hundreds of hours in the water and plenty of all-nighters spent, Puddles was a great AUV to work on and later revisit as a Masters Project in the 2022-2023 academic year.

Puddles was developed over the course of 2018-2019 and 2019-2020 school years. Competing in RoboSub 2019 the AUV placed 11th out of 55 teams and once again in 2020 placing 10th out of 33 teams. With hundreds of hours in the water and plenty of all-nighters spent, Puddles was a great AUV to work on and later revisit as a Masters Project in the 2022-2023 academic year.

Maelstrom - Competed in RoboSub 2018

Maelstrom was developed over the course of the 2017 – 2018 school year. It competed in RoboSub 2018, placing 10th out of 47 teams. The vehicle uses the main hull from Riptide but has a completely redesigned chassis. The chassis is a thin aluminum frame wrapped around from enhanced protection.

Maelstrom was developed over the course of the 2017 – 2018 school year. It competed in RoboSub 2018, placing 10th out of 47 teams. The vehicle uses the main hull from Riptide but has a completely redesigned chassis. The chassis is a thin aluminum frame wrapped around from enhanced protection.

Click to learn more about the cameras used!

Riptide 2.0 - Competed in RoboSub 2017

A revision of Riptide with the same main hull and a slightly redesigned chassis. It boasted upgraded sensors and maneuverability. Riptide 2.0 completed in RoboSub 2017 and was developed over the course of the 2016 – 2017 school year.

Riptide 1.0 - Competed in RoboSub 2016

UWRT’s premier AUV, competed in RoboSub 2016, and was developed over the course of the 2015 – 2016 school year. The design features a singular main hull with a minimally invasive aluminum chassis for mounting components.

Retired ROVs

Jaws

The team’s last competition ROV, featuring custom thrusters and a large dome for optics.

Block-O-Bot

An ROV full of school spirit. The vehicle made use of a watertight acrylic tube sandwiched between two OSU themed plates. Also featured on the bot is a custom manipulator arm.

Carbon Carmen

As its name would suggest, the Carbon Carmen is an ROV made primarily with carbon fiber. This design decision reduced weight and provided a great wow-factor.

Buckeye Boulder

The robot that started it all! The Buckeye Boulder is an ROV consisting of an open PVC frame that made use of a custom controller. We’ve come a long way since then!